BMW is undergoing a transformation in order to develop high-performance, electrified internal combustion engine and electric vehicle powertrains for the future.

For over a century, BMW's manufacturing facilities in Bavaria have produced some of the most legendary high-performance vehicles in the world. Looking ahead to the next 100 years, the company is revamping its entire operation to focus on a different kind of performance: battery technology, electric motors, and even robotic manufacturing.

At BMW, it's a high-risk and high-cost gamble that relies on its vision of the future mix of electric and internal combustion vehicles that will keep it profitable for generations to come.

Although BMW is one of the smaller car manufacturers - it's not as large as Audi, which can rely on the massive Volkswagen Group for support, for instance - the company's commitment to electrification is truly remarkable. This is especially noteworthy given the current political climate, which is increasingly focused on reverting to a time when transportation primarily relied on polluting fossil fuels.

As BMW continues to gradually release details about the new platform and features, the company is undergoing a significant transformation across its global supply chains and manufacturing facilities.

BMW's "Energy Master."

A behind-the-scenes look at how BMW is modernizing its oldest production lines to meet growing demand for electric vehicles. This involves staying current with, developing, and testing new battery technology as well as drawing from the tech sector to create new battery controller modules in the face of a slower-growing electric vehicle market.

For the United States, those models will be produced and shipped first in Europe, starting this summer, but they won't become available there until 2026 at the earliest.

BMW Plant Landshut

How BMW is Staying Ahead of the Curve in Battery Technology

Since the pandemic disrupted global supply chains, automobile manufacturers worldwide have reassessed their strategies for introducing electric vehicles and their battery packs to the market.

The shift signifies a substantial industry investment. In the United States, over $112 billion has been allocated to various local electrification projects mainly due to President Biden's infrastructure law and the Inflation Reduction Act (IRA).

Companies such as Mercedes, Toyota, General Motors, and others have established research facilities in the U.S. to focus on battery technology development. Their goal is to create batteries that will eventually rely less on heavy metals and non-renewable resources, and to pursue advancements in solid-state technology. Similarly, BMW has built on its experience and knowledge gained from introducing early electric models like the i3 and the i8, both of which were available to customers before other mainstream manufacturers, including Tesla, began to follow suit.

.

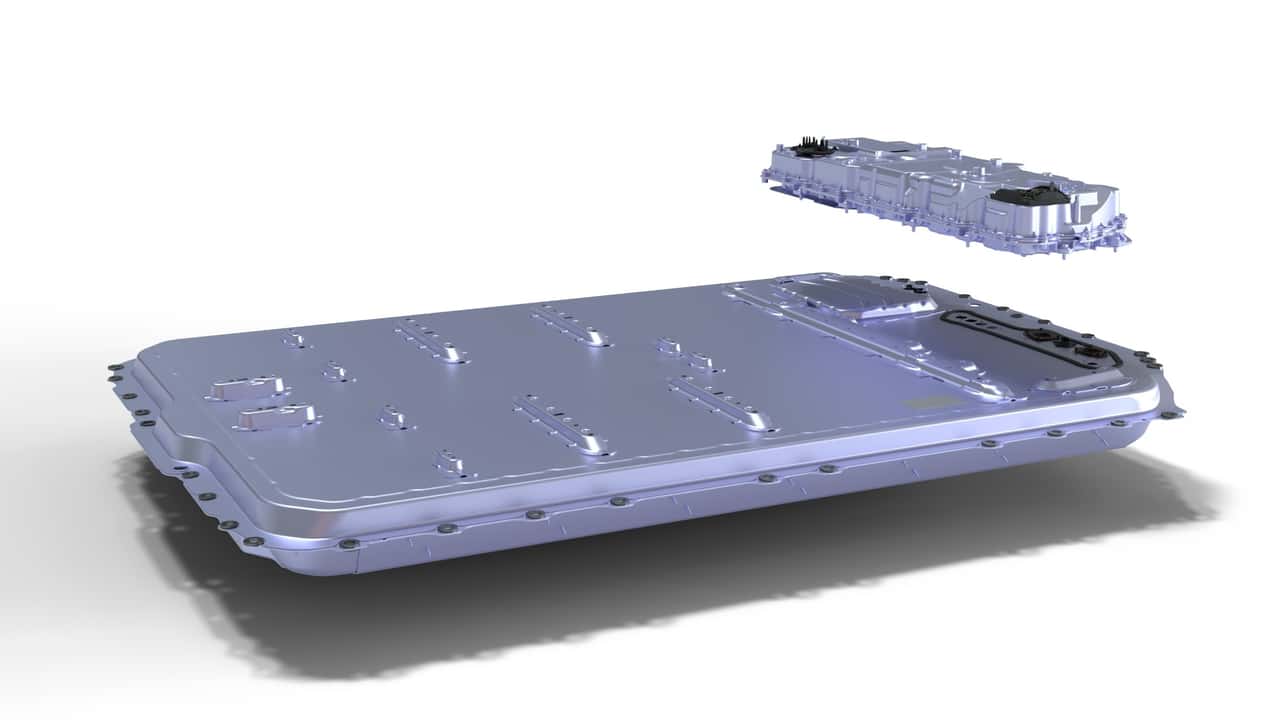

The upcoming batteries, developed by BMW, consist of a slurry applied to a thin copper sheeting, which is then rolled into cylinders, sealed, and filled with an electrolyte solution. The BMW Collaborative Cell Chemistry works closely with international academics to develop new battery technology, while the Cellular Manufacturing and Characterization Centre tests and scales up new battery technology for future electric vehicles.

BMW has a Cell Recycling Competence Center (CRCC). This facility employs both hydrometallurgy and pyrometallurgy, along with other battery recycling methods, to break down used batteries into their component parts so they can be reused in future batteries. The goal is to establish a fully circular battery production and recycling system that BMW can utilize for years to come.

That will not be the foundation of the Neue Klasse.

BMW VDX Neue Klasse

The objective of the three internal teams is to share any discoveries and advancements in electrification technology with suppliers to assess whether they can meet BMW's high standards and manufacture the battery technology reliably and on a large scale. A representative at the Parsdorf event stated that the aerospace industry had inquired about BMW's battery technology, but the company had declined the opportunity.

In the United States, BMW will introduce the battery technology developed and expanded in Germany at battery factories worldwide, a process the company refers to as "local-for-local." For instance, its brand-new battery factory, known as Plant Woodruff in South Carolina, is currently under construction and advancing rapidly. It represents a $700 million investment in the vicinity of BMW's Plant Spartanburg, which manufactures and exports the largest number of X3s globally.

BMW Neue Klasse

The investment also necessitates the massive retraining of thousands of employees who manufacture BMWs worldwide. To scale up training without disrupting production, BMW is utilizing various technologies, including gaming platforms, to ensure a smooth transition.

During the holiday period, Plant Spartanburg, located adjacent to still-under-construction Plant Woodruff, started transitioning to producing electrified X3s on the same production line as the ICE X3s. BMW utilized video game platforms such as Unreal Engine and Virtual Reality to train its manufacturing staff during the brief break. Associates developed a customized Virtual Reality training program on Unreal Engine to enable associates to learn the new processes for assembling electric vehicles. The technology enabled BMW to maintain the production line's operation while making the transition.

Upgrading and Rebuilding Plants and Manufacturing Facilities for the Neue Klasse

BMW's manufacturing facility in the heart of Munich is over a century old, and it is undergoing a massive renovation that involves both demolition and reconstruction at the same time to accommodate an increasing number of electric models on the three-level production line. This project represents a substantial investment of approximately $680 million and a complex logistical undertaking.

The plant currently manufactures 1,000 vehicles daily, and despite ongoing construction across its 4.3 million square foot premises, production has not been suspended. BMW currently produces both internal combustion engine vehicles and electrified vehicles on the same production line in Munich.

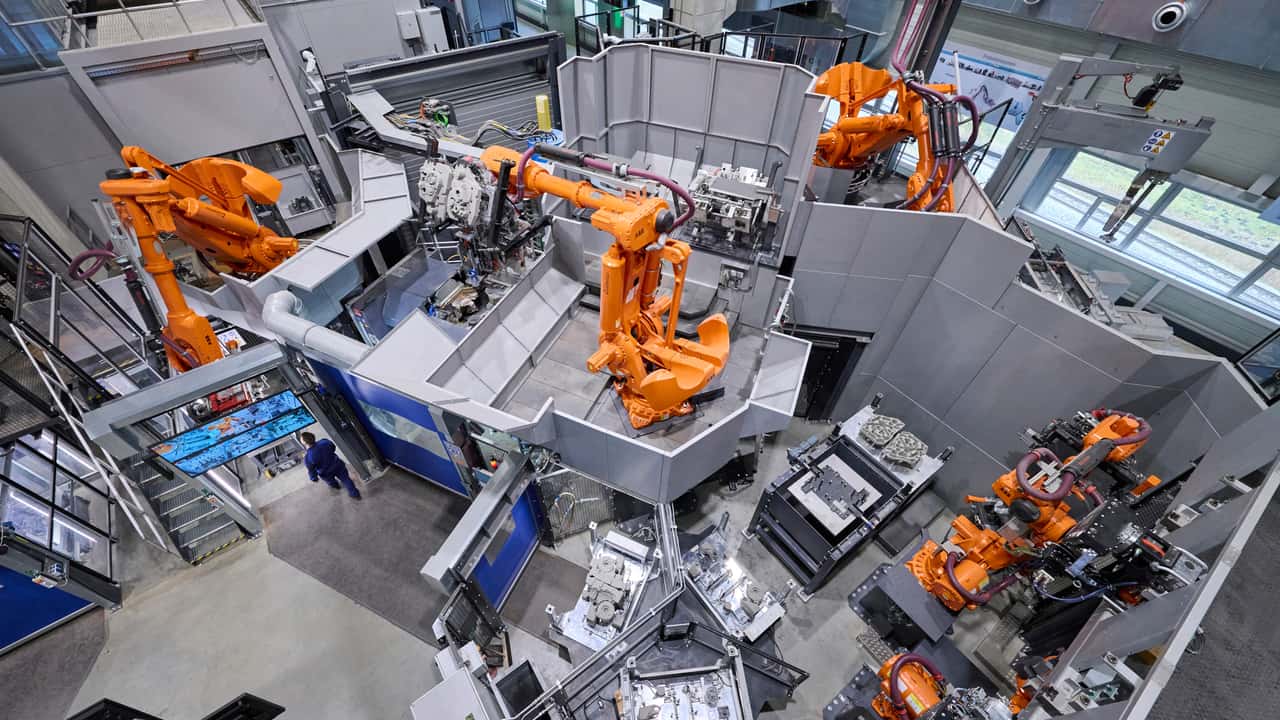

The BMW plant in Landshut, located approximately an hour northwest of Munich, is also undergoing a significant overhaul. Landshut, a specialist in lightweight powertrain materials and construction, is currently producing lightweight aluminum casings for the new asynchronous and electrically excited motors that BMW will use in the Neue Klasse. It is also the site where all the new "Energy Master" controllers for the battery packs will be manufactured globally.

BMW High-Voltage Battery

BMW has utilized insights and production methods from the technology sector to guarantee that all Energy Master control modules leaving the production line meet a high standard of quality and reliability. For instance, the Energy Master is manufactured in a clean room environment, primarily by robots, to ensure that no dust or debris enters the controllers. The company is currently cooperating with KUKA robotic arms, but also experimenting with smaller robots that can delicately pick up, grasp, and connect wiring harnesses in the Energy Master, a task that is currently performed by humans in the plant.

Once the Energy Masters are assembled and sealed, human experts will review the robot's work. The Energy Masters will then be shipped from Landshut worldwide to be attached to locally built batteries for the Neue Klasse vehicles.

It is reported that the plant will begin mass production in August, according to the company.

BMW Neue Klasse EV Concept

A Globally Adaptable Production Line for Electric Vehicles

The automotive manufacturing industry was heavily impacted by supply chain disruptions and semiconductor shortages during the pandemic, and companies such as BMW have utilized the knowledge gained from those experiences to establish more robust domestic supply networks.

To minimize supply chain disruptions and reduce costs, the company has invested in battery technology for its Neue Klasse and manufacturing facilities for its new electric vehicles.

There is no original text provided. Please provide the text to be paraphrased.

“Everyone is wondering about this, and I believe it's one of the main concerns at the moment,” said Joachim Post, a member of the BMW board, during a roundtable discussion in Landshut. “The positive aspect is that we don't need to alter our strategy.”

The company has stated that it follows an "open technology approach, with a global presence worldwide." This enables it to adapt its individual offerings to suit the needs of each market.

“From the supply chain perspective, we are also adopting a local-for-local approach,” Post said. “Our philosophy is that production aligns with market demand, and the supply chain adapts to production. We have a significant presence in the U.S. We are the leading exporter by value from the U.S. and Germany, and sometimes people overlook these facts.”

BMW Board Member Post.

Despite facing challenges in the US market, particularly with the current administration's efforts to restrict electric vehicles, BMW remains committed to its electrification strategy. The company is undeterred by the potential impact of tariffs, with Post saying that BMW is confident in the future of electric vehicles and will continue to offer customers a range of options, including fully electric and internal combustion engine vehicles, through its manufacturing lines.

It's a growing market, and we're performing well because of our extensive portfolio in every relevant segment, with at least one BEV," Post said. "I believe this is a clear advantage, and it aligns with our technology-neutral approach because markets and customers choose the technology they prefer.

BMW Neue Klasse Grille

The Atlantic, Elle Magazine, National Geographic, Travel & Leisure, Fast Company, Inc., Fortune, The Verge, TechCrunch, CNN

More BMW EV News

- Future Mini EVs May Shift to Rear-Wheel Drive

- BMW's New Class EVs Will Feature Three- and Four-Motor Cars

- BMW's New Class EVs Will Have Up to 560 Miles of Range

- Tesla's Full Self-Driving Technology May Become a Trade War Bargaining Chip in China.

- BMW's Mind-Blowing, 9,600 kg-m Vision Driving Experience Demonstrates the Electric Vehicle Future Will Be Unpredictable

- BMW: Electric Vehicles with Large Batteries 'Do Not Make Sense'