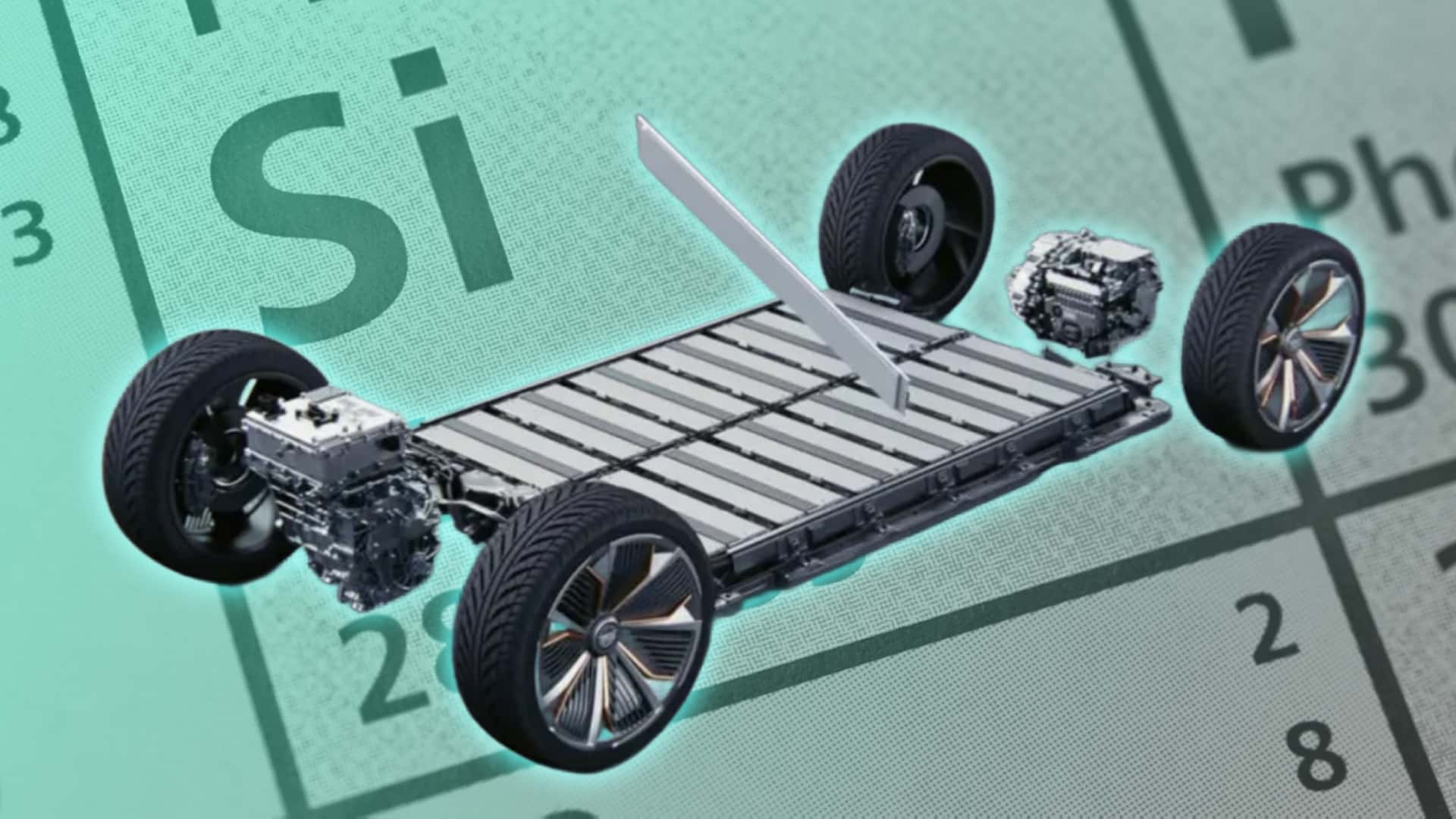

Silicon-based anodes enhance charging efficiency and extend driving distances. General Motors asserts that the United States is well-suited to adopt this technology.

- Silicon anodes have made more progress in development and commercialization than solid-state batteries.

- Manufacturers of batteries are striving to increase the silicon content in order to enhance driving distance and decrease charging time.

- General Motors forecasts an expansion of silicon content in EV batteries over the coming years.

There is one way to arrive.

"You're going to see more silicon incorporated into EV batteries because it offers enhanced range and also facilitates faster charging," Cintra said.

In an electric vehicle battery, the anode is the electrode where lithium ions are stored when the battery is being charged. It usually consists of graphite-based materials. Specialists claim that the anode's material and design directly affect the EV's performance, and using a higher silicon content can enhance that. Silicon-containing anodes have been available for the past few years, albeit in small quantities. However, that is poised to change.

When asked if GM's electric vehicles will feature silicon anodes by the end of the decade, Cintra replied, "We would certainly like to see that. We have a lot of other technologies we're trying to implement, and silicon is one of those."

Approximately 50 to 70% of raw graphite is lost during the process of upgrading it to battery-grade quality, rendering the process inefficient and exacerbating supply chain issues due to heightened material demand.

Silicon is a promising alternative because it offers more efficient energy storage and accelerates the charging and discharging processes.

Similar to several other new battery technologies, mass production is challenging due to the need for complex and time-consuming processes that consume a lot of energy and resources. Nevertheless, battery manufacturers are striving to streamline these processes, and they've already achieved some progress, with further advancements expected in the future.

The battery manufacturer stated that it can decrease a vehicle's weight by several hundred kilograms.

Several U.S. battery start-ups, including Amprius, Group 14, and Sila Nanotechnologies, are also competing to develop silicon anodes.

Sila's silicon anodes are currently being used in the electric Mercedes-Benz G-Class. Yet, this EV has a range of only 239 miles according to the EPA and can charge from 10-80% in 32 minutes on a 200 kW charger. Sila hasn't disclosed the percentage of silicon in the G Wagen's anode. It remains unclear if it uses a 100% silicon anode, which seems unlikely given its charging efficiency—it may be using a small amount of silicon in the existing graphite anode to compensate for its weight and aerodynamic issues.

achieved an impressive 506 miles of range in a real-world test. But the 8,800-pound truck delivered an abysmal efficiency of 48.1 kWh per 100 miles, or 2.0 miles per kWh. Innovations on the battery front may solve that.

As new materials such as silicon anodes and advanced cathodes become available, battery sizes will decrease," Cintra stated. "As production volumes rise, the adoption rate will accelerate, leading to lower prices.

Have a suggestion? Reach out to the writer:

Related Stories

- Solid-State Batteries Are in Innovation Overdrive. What's Delaying Their Advancements?

- Silicon anode electric vehicle batteries have great potential, but the situation is complex.

- Renault Achieves a Significant Breakthrough in Electric Vehicle Fire Safety, and Now Other Companies Can Utilize This Innovation at No Cost.

- The Scout Range Extender will be a non-turbo four-cylinder engine, providing a 500-mile range.